Description

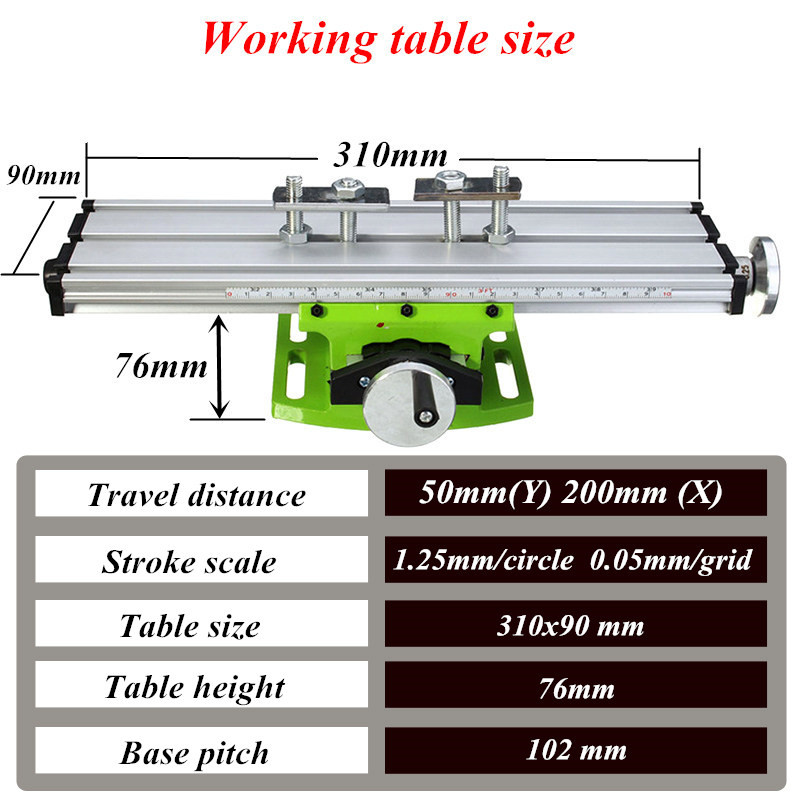

Specification:

Model: BG6300

The lead screws are M8X1.25

PAGE0:

Dear Customer: Hello!

First of all thank you for purchasing the company’s products, hoping to give you the work and life to bring greater convenience and endless fun! Before using the technology, please be sure to read this manual in detail, you must follow the instructions in the instructions required for safe operation.

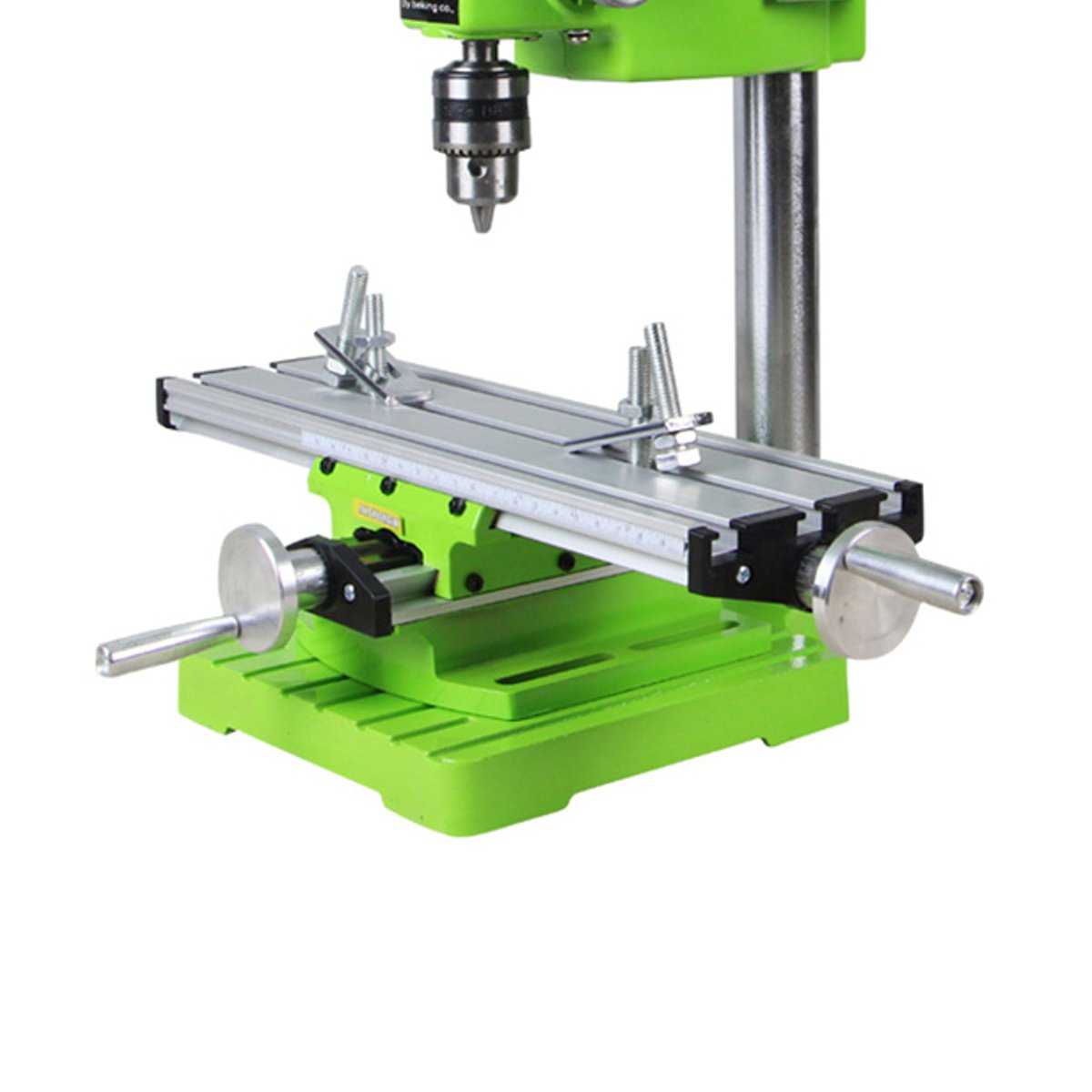

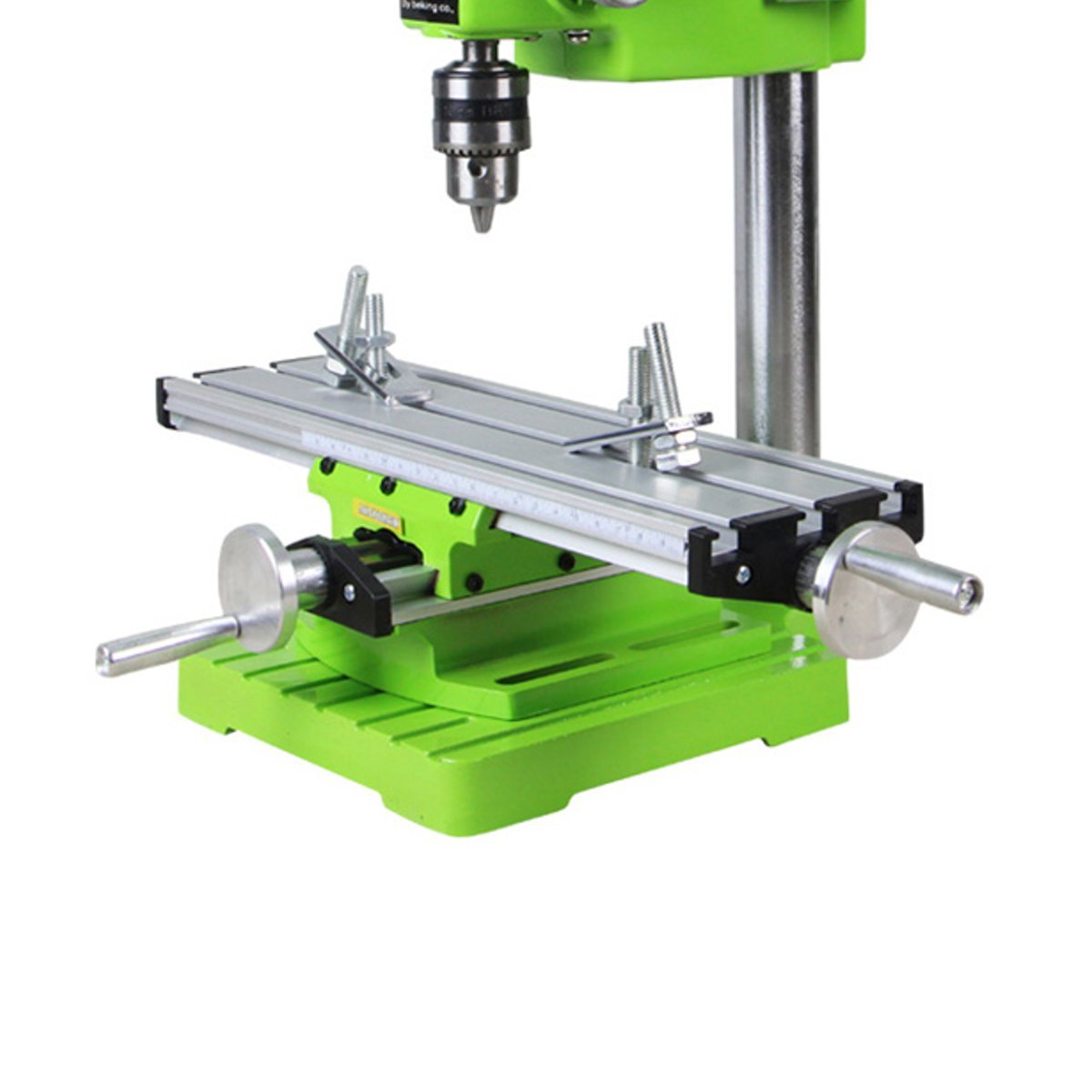

The multi-purpose table with bench drill can be used as a milling machine to achieve high precision coordinate drilling and small milling.

When using this table, be sure to follow the appropriate safety practices for bench drills and milling machines, and keep in mind that the coordinate table is a sophisticated, miniature, easily damaged tool, so be sure to keep your care , And do the necessary protective measures to ensure the use of safety. please

PAGE1:

Mini Multifunction Workbench User’s Manual

Technical Data

Model BG-6300

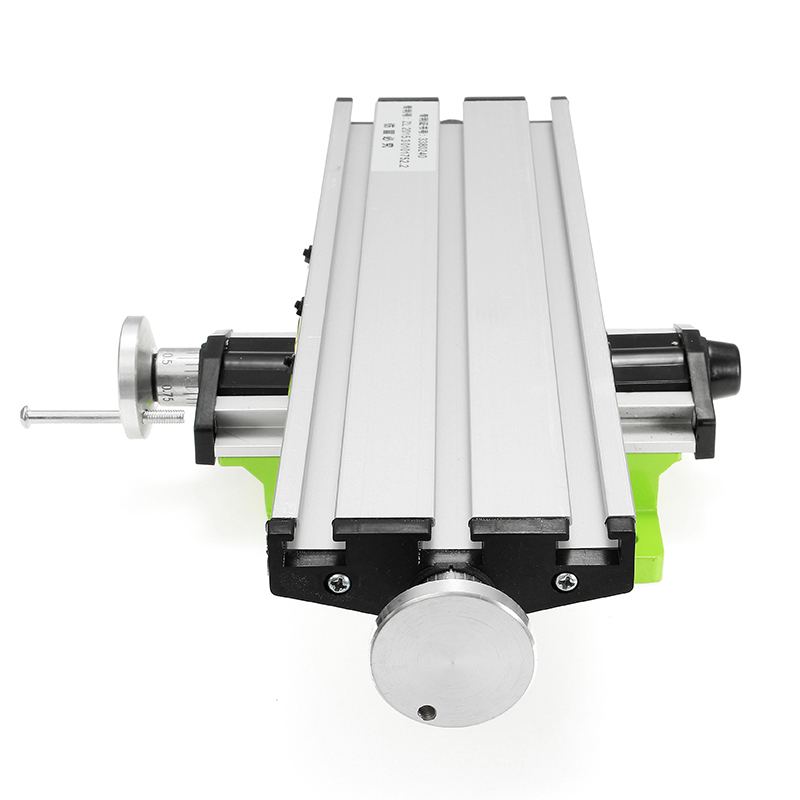

Worktable Size 310×90

X-Axis Travel 200…

Y-Axis Stroke 50…

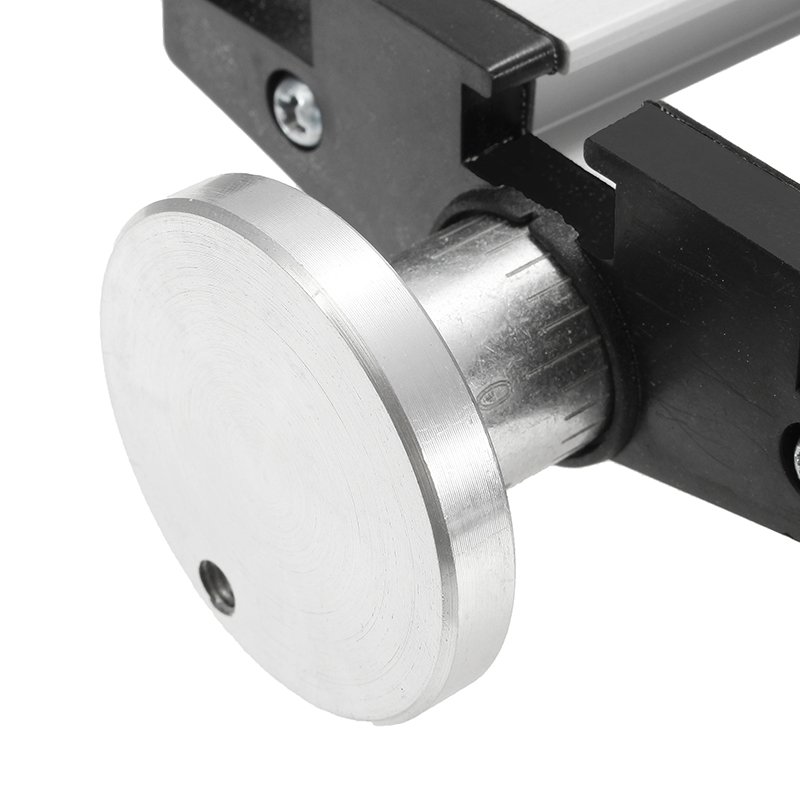

Rotation Knob One-way stroke 1,25 1.5…

Clamping groove pitch 34…

Note: The above data unit is mm Please check the product packaging is intact, open the package, the mini multi-purpose table placed on the flat table (according to (Figure 1) first familiar with the important components of the table (6300 example).

Figure 1

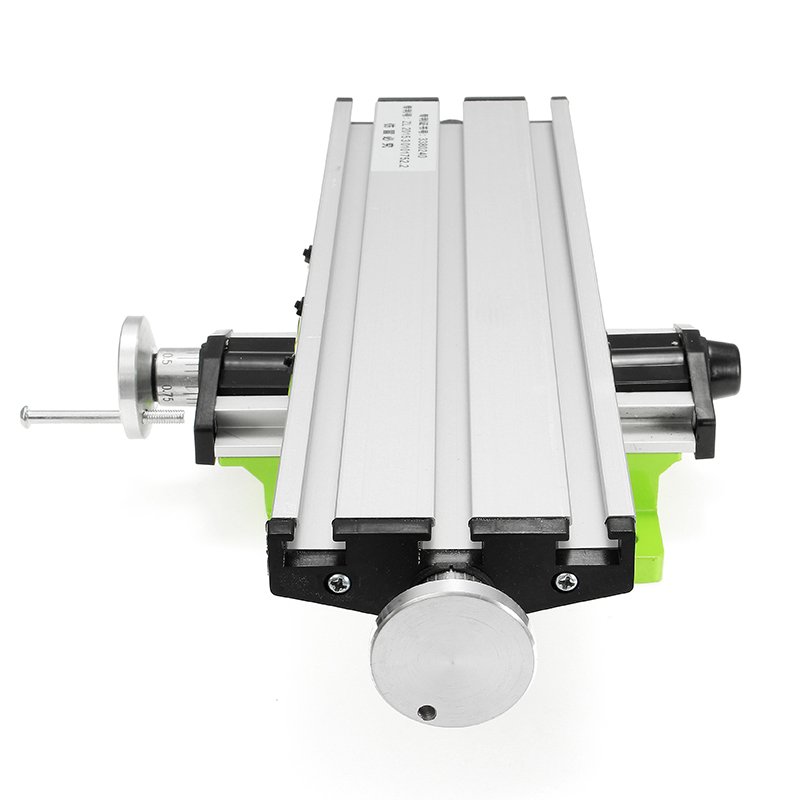

Workbench

Workbench End Cover

Adjustment Screw

Activity Table

Handwheel

Base Plate

End Cover

Base

PAGE2:

Warning: Please do not overload the use, or prone to deformation, broken and other damage and dangerous accidents!

[Installation] 1. Installation of the fixed table The multi-purpose table for the use of small drill and drill stand design, the base with a screw mounting slot, just use the M8 screw nut can be fixed with the bench drill or drill bracket base.

Usage

1, set the scale on the hand wheel on the scale circle is rotatable, can be set to “0” bit to facilitate viewing, calculate the feed, in addition to the table is also equipped with a movable scale to adjust the axis.

2, adjust the guide clearance C6300 / 6330 models) before or after the initial use of long-term use, you must first check the gap between the dovetail and guide rails, if the multi-function table rail clearance is too large or too small, you need to adjust the screw (26), and then adjust the adjustment screw (27) to set the gap, and finally re-lock the nut.

Note: adjust the screw do not twist too tight, otherwise the gap is too small, moving resistance, and even damage the guide: too loose gap, will produce swing, the impact of precision

3, timely lubrication and cleaning 6350 linear guide and linear bearings need Timely add lubricants, rails and screw to be cleaned in time.

4, the speed and processing of the processing of different materials of the workpiece should be different feeding speed and processing capacity.

Overloading or excessive force is likely to cause damage to the workpiece, tool, and bench or table.

PAGE3:

5, clamping the workpiece 6300: accessories with a punch of plywood, by adjusting the height of the top of the screw and the nut under the tightening of the nut to clamp the workpiece.

(Figure 2) 6330,6350: Annex with a set of fine pliers, clamping the workpiece see (Figure 3) Figure 2 Figure 3 [different models of the characteristics and recommendations] BG-6300 basic multi-function table, Affordable, suitable for general use.

BG-6330 boutique multi-function table on the basis of BG-6300 new improved research and development products, the end cap to a more solid aluminum alloy material: to increase the flat bearing rotation more flexible; base and active pedestals are strengthened rigid structure:

Thick screw specifications; can be used for higher requirements. BG-6350 heavy duty multi-function table, in addition to suitable for DIY use, but also competent for the production line on the use of the requirements:

Special Recommendation: BG-6350 with auxiliary motor bracket components, with the company’s BG-3306 woodworking lathe Combined into a set of Buddha beads machine, Buddha beads of the production effect is very good!

PAGE4:

1 Capping cap

2 hexagonal locking nut M10

3 flat bearings

4 crosshead head tapping screw M4x 16

5 work plate end cover

6 workbench

7 scale

8 screw nuts

9 Upper Adjustment Plate

10 activity stand

11 lower adjustment plate

12 short screw

13 screw bushing

14 scale ring

15 cylindrical pin

16 hand wheel

17 handle

18 base

19 base table

20 lower telescopic protective cover

21 under retractable cover

22 base plate end cap

23 cross plate head Screw M3x6

24 spring pad

25 cross plate head screw M5x16

26 hex nut M14

27 Hexagon Socket Head Cap Screw M4x12

28 long screw

or 4 payments of

or 4 payments of

Reviews

There are no reviews yet.